Keeping the Crunch

I can’t believe this is my first At The Core post of 2024! At this time of year, I’m really not working much at the farm. My role as Upick Manager is very much fall-centric. And although I do some social media posts here and there, as well as light planning for the coming season, I also really enjoy this slower time of year.

I’ve been relishing the time away from living and breathing apples 24/7 – but I will tell you, I am still eating our apples every day - and they are so good! The other day I brought some of our LynOaken Farms apples to an event and someone asked me, surprised, “Oh! You have apples already?” And I answered “No, we have apples still!”. The apples that I brought to that event (and the apples I eat every day, and the apples you eat every day) are from last year’s harvest. Apples are an extremely seasonal fruit. Not only do they take a whole year to develop, but they are only harvested in the small two-month window of September and October (here in NY, at least). That means that every apple you see on the market today in March was harvested the previous fall, nearly six months before.

Apples have, for hundreds of years, been harvested in the fall and then stored for later use. But how they’re stored has changed a lot over the years.

A long time ago, before refrigeration and electricity, apples would have been stored in a root cellar. Those apples would have been used for baking or cider, so their fresh-eating quality was not the priority. As apple varieties shifted and people began selecting the more “dessert” quality fruit to grow, they wanted to preserve not only the flavor, but the texture of the apple as well. But if you’ve ever had an apple that was sitting in a fruit bowl for too long, or found a rogue fruit rolling under the backseat several weeks after your apple -picking adventure at LynOaken Farms, you know that an apple only stays crisp for so long.

Apples (like all fruit) produce a hormone called ethylene that promotes ripening. Ethylene is the reason why you can stick a rock-hard peach in a bag with a ripe banana and have it ripen quicker than if it was just sitting on your counter. Ethylene is responsible for the fruit ripening on the tree, but it also continues to be produced by the fruit post-harvest. And since apples should only be picked when they are at their peak ripeness, once they’re off the tree, any ethylene produced after harvest will cause the fruit to soften and break down.

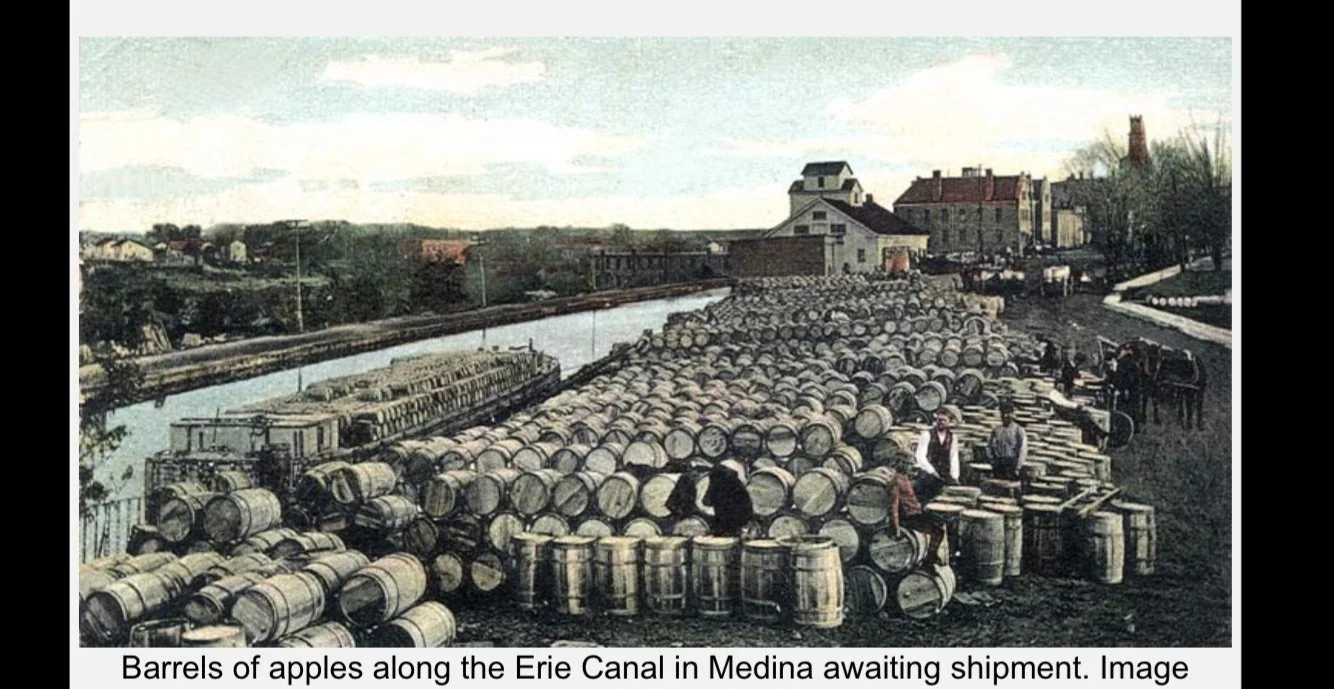

The key to prolonging storage life and ensuring a crisp crunchy apple months after it is picked is to slow down that post-harvest ethylene production as much as possible. Cold temperatures (just above freezing) will help. In fact, when the fruit belt of NY was really starting to boom in the late 1800s/early 1900’s, apple storage became big business at points of commerce all along the Erie Canal and railroads across northern NY. The apples harvested in this region would be packed into barrels, then stored in big stone buildings cooled by ice harvested from local lakes until they were sold and shipped out. But cool temperatures only slowed the ethylene production down to a point. Apples still had a pretty limited shelf-life of optimal eating quality.

Enter Controlled Atmosphere (or CA) storage. Initially developed at Cambridge and then improved at Cornell, CA Storage not only kept the fruit at the optimal cool temperatures needed to slow ethylene production, but the system modified the air inside the storage rooms – reducing oxygen so much that essentially the fruit stops its normal ripening and aging process. Once an apple enters a CA storage room, it is figuratively “frozen in time”. Whatever state the fruit was in when it went in to a CA storage room is pretty much the state that it will be in when that room is opened and fruit is removed for sale.

At LynOaken Farms, all of our apples are picked at peak ripeness – there is about a 7-10 day window for harvest for each variety. And then every single one of those apples that isn’t sold within a few days is stored in our CA storage facility. We are lucky enough to have CA storage on site at our Ridge Road farm location. Farm trucks roll in daily during harvest, loaded with the big 800lb bins of apples. Those bins are then stacked carefully into individual refrigerated storage rooms (we have 12 at our facility). Once the rooms are full (around 700 bins … I’ll do the math for you – that’s 560,000 lbs of apples in each room!), they are sealed and the oxygen inside is reduced from the normal everyday atmosphere levels of 20% down to the prime apple storage levels of 2%. And there the apples will stay, sitting pretty at peak ripeness until it’s their turn to be sold. The rooms are opened, one by one, from November though May or June (if it’s a good year!), ensuring a steady supply of delicious, crisp apples that taste like they were just picked from the tree!

Not all orchards have their own CA Storage, and our harvest alone wouldn’t fill all the rooms. So we rent space to other growers during harvest – not only optimizing the space at our facility, but also benefiting the other growers who want delicious, crisp, freshly-picked-tasting apples in May as well!

Whew! That’s a LOT of information! And isn’t it so cool?!? I know that some of you will join me in nerding out about the amazing advances agriculture has made over the past centuries and the rest of you might just be content to crunch into your crispy apple and appreciate that someone else is making sure your snack is as perfect as it can be! Either way, at the core, I think we can all agree that crisp and crunchy apples are better than soft and mushy apples, and that shan’t be taken for granted!

-Katie